Application Evaluation Summary

A company located in Tianjin, China, used the Cold Jet i3 MicroClean to clean melt blown filter from Spinneret-holes. It currently causes 10-20 hours of downtime to clean these molds. Dry ice blasting is a fast, easy and non-abrasive cleaning process that uses no water or chemicals and sublimates into a gas on impact—leaving no secondary waste. Using the Cold Jet i3 MicroClean enabled fantastic, quality cleaning to be achieved in 12 to 20 minutes for one mold from around 600mm long.

The evaluation was performed on April 28, 2020

Customer information

Application Description

|

Contaminant |

POLYPROPYLENE material used for production of melt blown filter forming the middle layer of Medical Surgical Face Masks |

|

Substrate |

Spinneret-holes, diameter of 0.2-0.25 mm, depth of 1-2mm |

Application Evaluation

|

Notes |

The Cold Jet i3 MicroClean machine is used to blast MicroParticles, which are accelerated to supersonic speeds and clean through the 0.2mm diameter spinneret holes without creating secondary waste. The impact of dry ice blasting will not damage the spinneret holes. In addition, the food grade dry ice is safe and clean without hazardous substances. |

|

Current Cleaning Method |

High Pressure water jet , chemicals, ultrasonic bath, manual scraping and pinching |

|

Other |

Heating (in a vacuum furnace). |

|

Pain Points |

Currently, every 4 to 5 days the molds need to be disassembled and cleaned to avoid quality issues and rejections of the finished goods (Face Masks). The cleaning is usually outsourced to cleaning companies, which apply a combined cleaning method of heating (in a Vacuum Furnace), High Pressure water blasting, chemicals, ultrasonic bath, manual scraping and pinching. The entire process is causing a downtime of minimum 10 -20 hours up to several days, causing a massive production capacity loss. This can be significantly reduced by using the proven Cold Jet dry ice cleaning method. |

|

Total Time Needed with Current Cleaning Method |

At least 10 to 20 hours per mold, depending on the length of the mold. Manufacturers have to invest in additional (back-up) molds (very expensive – 1.6m long mold costs 2,000,000CNY) or accept the production capacity loss (also very expensive – 1 day of production means in some cases +/- 1,500,000 CNY). |

|

Customer Machine Videos |

|

|

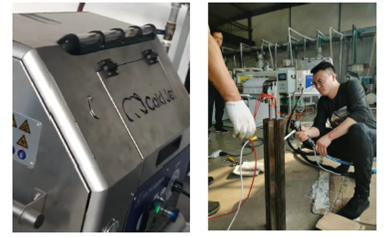

Picture of System Setup |

|

|

Picture of Machine Settings / Display |

|

|

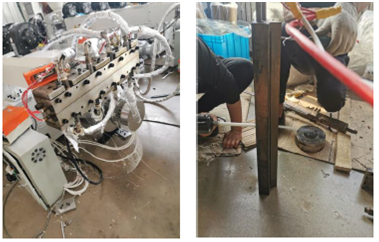

Before & After Pictures (2, 4 or 6) |

|

| General Cleaning pictures |  |

|

Cold Jet System Used |

i3 MicroClean |

|

Cleaning Result Description |

Using this Cold Jet dry ice cleaning machine with the smallest size of dry ice MicroParticles accelerated to supersonic speed allows us to clean through the spinneret holes without creating secondary waste. The impact of the dry ice particles will not damage the spinneret holes nor other parts of the mold. In addition, the food grade dry ice is safe to use and clean without hazardous substances. |

|

Cold Jet Cleaning Time |

Takes about 15 to 20 minutes for one mold, 600mm long (after heating). |

|

Nozzle Type |

MC19 (Part #: 5E0478) and MC88 (Part #: 5E0532) or MC13 (Part #: 13865-126) |

|

Dry Ice Type |

Block |

|

Compressed Air Pressure (BAR) |

7-8 Bar |

|

Blast Pressure (BAR) |

7-8 Bar |

|

Feed Rate |

0.2kg/min with MC19; 0.15Kg/min with MC13 |

|

Additional Comments |

The mold will not be damaged by changing mold temperature of a few degrees lower with dry ice blasting. MicroParticles can enter the spinneret holes and remove contaminants thoroughly. Dry ice blasting is non-abrasive and the solid dry ice particles will turn into natural carbon dioxide gas upon impact, without damaging the mold or causing problems for the operator or the environment |

Financial Benefits

|

Economic Value |

Significant production capacity increase for the producers of Face Masks, while reducing the risk of product quality issues and rejection of finished goods (estimated at +/- 1,500,000 CNY per day of production). Little to no investment in back-up molds (estimated at 2,000,000CNY per mold for a+/- 1.6m long mold). Estimated payback time: from less than one week up to maximum of one month depending on the size of the production facility. |

General Benefits

|

General Benefits of Cold Jet |

|

General Information

|

Cold Jet |

|

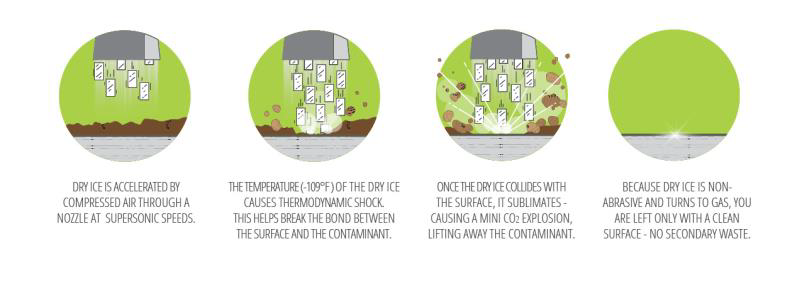

| How It Works |  |

Recommended System Configuration

|

The i3 MicroClean® |

|

| AERO2 PCS 60 |  |

Media Upload

|

Video 1 |

|

|

Video 2 |

|

|

Video 3 |

|

|

Video 4 |

|

|

Video 5 |